Electronics Conformal Coating Market Set to Soar to US$ 2.8 billion by 2033

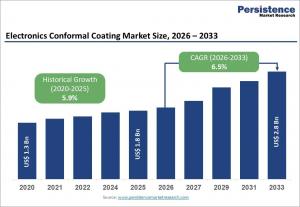

The global electronics conformal coating market is set to grow from US$1.8 Bn in 2026 to US$2.8 Bn by 2033, expanding at a 6.5% CAGR from 2026-2033

BRENTFORD, ENGLAND, UNITED KINGDOM, February 2, 2026 /EINPresswire.com/ -- The global electronics conformal coating market is witnessing steady growth, driven by increasing demand for advanced protection in electronic devices. Valued at approximately US$ 1.8 billion in 2026, the market is projected to reach US$ 2.8 billion by 2033, registering a CAGR of 6.5% during the forecast period. The rise in consumer electronics, miniaturization trends, and stringent environmental regulations are among the primary factors propelling market expansion.

Acrylic coatings currently dominate the market due to their ease of application, quick drying times, and cost-effectiveness, capturing nearly 44% of the market share in 2025. Geographically, Asia Pacific leads the industry, contributing around 45% of global market share, thanks to its robust electronics manufacturing hubs in countries like China, Japan, and South Korea. The region is also witnessing accelerated electric vehicle (EV) adoption and IoT deployments, which further bolster demand for protective coatings.

𝐆𝐞𝐭 𝐚 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐁𝐫𝐨𝐜𝐡𝐮𝐫𝐞 𝐨𝐟 𝐭𝐡𝐞 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.persistencemarketresearch.com/samples/33399

Key Highlights from the Report

Asia Pacific dominates the market with 45% share in 2024.

UV-curable coatings are the fastest-growing segment at an 8.5% CAGR.

Acrylic coatings remain the leading product segment at 44% share.

Aerospace and defense applications present high-growth opportunities.

The global market value is projected to reach US$ 2.8 billion by 2033.

Market CAGR is forecasted at 6.5% between 2026 and 2033.

Market Segmentation

The electronics conformal coating market is primarily segmented by product type, application, and end-user industries. By product, the market includes acrylic, silicone, polyurethane, epoxy, and UV-curable coatings. Acrylic coatings dominate due to affordability and ease of use, while UV-curable coatings are gaining traction because of rapid curing capabilities and low volatile organic compound (VOC) emissions. Epoxy and silicone coatings are preferred for high-temperature or harsh environmental conditions, often applied in automotive and industrial electronics.

From an end-user perspective, segments include consumer electronics, automotive, aerospace & defense, industrial electronics, and telecom. Consumer electronics remain a leading application, driven by smartphones, tablets, and wearable devices, whereas automotive electronics are expanding rapidly with EV growth. Aerospace and defense coatings are critical due to stringent performance requirements, while industrial electronics benefit from conformal coatings to enhance equipment longevity under challenging conditions.

𝐃𝐨 𝐘𝐨𝐮 𝐇𝐚𝐯𝐞 𝐀𝐧𝐲 𝐐𝐮𝐞𝐫𝐲 𝐎𝐫 𝐒𝐩𝐞𝐜𝐢𝐟𝐢𝐜 𝐑𝐞𝐪𝐮𝐢𝐫𝐞𝐦𝐞𝐧𝐭? 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐚𝐭𝐢𝐨𝐧 𝐨𝐟 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.persistencemarketresearch.com/request-customization/33399

Regional Insights

Asia Pacific is the largest regional market, supported by a dense electronics manufacturing ecosystem, rapid EV production, and government incentives promoting high-tech manufacturing. Countries like China, Japan, and South Korea serve as global supply chain hubs for electronics, significantly boosting conformal coating demand.

North America and Europe are seeing steady growth, primarily fueled by industrial automation, telecom infrastructure expansion, and aerospace modernization programs. North America, in particular, is leveraging 5G network rollouts and defense sector upgrades, which increase the adoption of protective coatings for sensitive electronic components.

Market Drivers

The electronics conformal coating market growth is propelled by the surge in consumer electronics demand, which exceeded US$ 1.2 trillion globally in 2025. Increased adoption of electric vehicles also drives growth, as automotive electronics are projected to constitute over 50% of total vehicle costs by 2030. Moreover, rising IoT and 5G infrastructure deployment creates a need for robust coatings that protect sensitive components from moisture, dust, and thermal stress.

Market Restraints

Despite growth prospects, the market faces challenges such as high material costs and complex application processes, particularly for UV-curable and high-performance coatings. Environmental concerns over VOC emissions and the need for strict regulatory compliance also pose barriers, especially for manufacturers seeking to balance performance with sustainability requirements.

Market Opportunities

Opportunities abound in aerospace, defense, and industrial electronics, where coatings are critical for high-reliability applications. The increasing adoption of drones, UAVs, and advanced defense systems creates new avenues for growth. Additionally, the development of low-VOC, eco-friendly coatings and UV-curable solutions presents untapped potential for manufacturers targeting sustainable electronics applications.

𝐁𝐮𝐲 𝐍𝐨𝐰 𝐭𝐡𝐞 𝐃𝐞𝐭𝐚𝐢𝐥𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.persistencemarketresearch.com/checkout/33399

Reasons to Buy the Report

✔ Gain insights into the latest trends, drivers, and restraints in the electronics conformal coating market.

✔ Access detailed segmentation analysis by product type, end-user, and region.

✔ Evaluate regional growth opportunities and market forecasts for strategic planning.

✔ Identify key players, market shares, and recent developments.

✔ Leverage data-driven insights to strategically enter or expand in the conformal coating sector.

Frequently Asked Questions (FAQs)

How Big is the Global Electronics Conformal Coating Market?

Who are the Key Players in the Global Electronics Conformal Coating Market?

What is the Projected Growth Rate of the Electronics Conformal Coating Market?

What is the Market Forecast for Electronics Conformal Coating by 2032?

Which Region is Estimated to Dominate the Electronics Conformal Coating Industry through the Forecast Period?

Company Insights

Key Players Operating in the Market:

Henkel AG & Co. KGaA

Dow Inc.

3M Company

H.B. Fuller

Electrolube Ltd

LORD Corporation

Shin-Etsu Chemical Co., Ltd

Recent Developments:

Henkel launched a new low-VOC conformal coating series for automotive electronics in 2025, enhancing environmental compliance.

Dow Inc. introduced a UV-curable coating solution with faster curing times and improved thermal resistance for 5G infrastructure in 2026.

Related Reports:

Business Intelligence Platform Market

Pooja Gawai

Persistence Market Research

+1 646-878-6329

email us here

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.